Recently, Professor Zhu Shengli's research team on metal functional materials from the School of Materials Science and Engineering, Tianjin University, in collaboration with Tohoku University (Japan), Johns Hopkins University (USA), and Professor Chen Mingwei from Southern University of Science and Technology, published a research paper titled "Tuning Electrocatalytic Activities of Dealloyed Nanoporous Catalysts by Macroscopic Strain Engineering" in the internationally renowned materials journal Nano Letters. PhD student Li Qite, from the 2020 cohort, is the first author of the paper.。

Transition metals play a critical role as active catalysts in many energy-related chemical and electrochemical reactions due to their abundant natural resources, multiple oxidation states, and unsaturated d-electron orbitals. Strain engineering is an effective strategy for enhancing the catalytic activity of transition metals, as lattice strain can shift the d-band center of the catalyst, thereby modulating the adsorption energy between the catalyst and reaction substrates or intermediates. However, experimentally applying lattice strain directly to nanoparticle catalysts is challenging, particularly in terms of quantitative methods. Most studies introduce lattice strain through lattice mismatch and defect engineering, but these approaches often lack precise control.In contrast, macroscopic strain engineering enables the direct application of strain via external loading, allowing precise regulation of catalytic activity. Dealloyed nanoporous catalysts have garnered significant attention in recent years due to their unique continuous nanoporous nanostructures, large specific surface area, and excellent electrical and thermal conductivity. These properties facilitate electron transfer, provide abundant active sites, and are suitable for high-precision catalytic performance studies.This study designed an in situ strain experiment to quantitatively measure the intrinsic relationship between macroscopic bending strain and the hydrogen evolution reaction (HER) activity of nanoporous gold (NPG) catalysts.

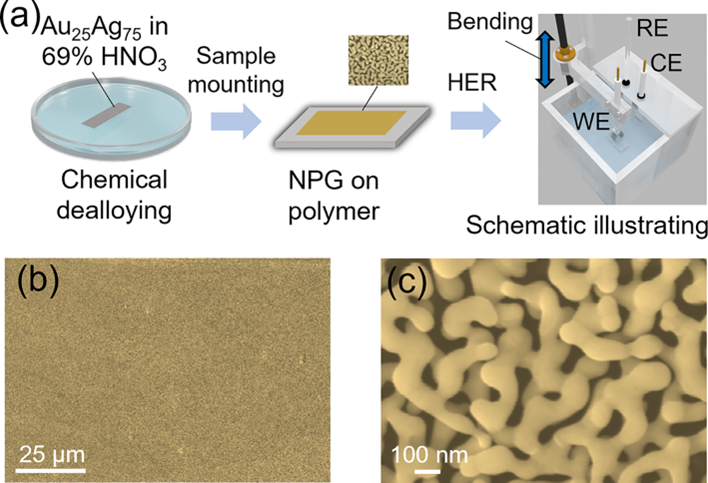

Figure 1. (a) Schematic diagram showing the sample preparation of nanoporous gold (NPG) and the hydrogen evolution reaction (HER) measurements of macroscopically strained NPG films. (b-c) SEM images of as-prepared NPG film with microscopic homogeneity and nanoscale porosity.

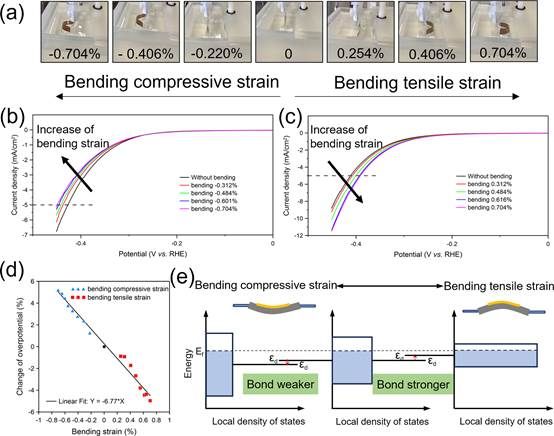

Figure 2. (a) Illustration of NPG film with different bending strains during HER measurements. HER performances of NPG at different bending strains: (b) bending compressive strains; (c) bending tensile strains; (d) the bending strains dependence of HER overpotentials at the current density of 5 mA/cm2; and (e) Schematic illustration of d-band center changes with bending. The compressive strains shift the d-band center downward, resulting in weaker binding to reaction intermediates while the tensile strains lead to the opposite results of upward shift of the d-band center and strengthened binding with reactants.

In this study, nanoporous gold (NPG) films with uniform nanoporous structures were prepared using a chemical dealloying method. Macroscopic bending deformation was employed to apply macroscopic strain, ensuring precise strain control. The results revealed that macroscopic compressive strain reduced the HER activity of NPG, while macroscopic tensile strain enhanced its HER catalytic activity, aligning with the d-band center model. The onset potential of HER exhibited an approximately linear relationship with the applied compressive/tensile strain within a strain range of 0.704%, indicating that from compression to tension, every 0.1% change in lattice strain decreases the binding energy between the catalyst and intermediate products by about 2.9 meV.

This highly strain-sensitive electrocatalytic method developed in this study opens new avenues for high-precision investigations of strain-dependent electrocatalysis and provides fresh insights for the efficient utilization of nanoporous catalysts in the future.

文章链接:https://pubs.acs.org/doi/10.1021/acs.nanolett.4c00781

文章DOI号:10.1021/acs.nanolett.4c00781